Full automatic pet blow molding machine is suitable for blowing PET plastic container and bottles in all shapes. The pet stretch blow moulding machine is widely used to produce the carbonated bottle,mineral water bottle,pesticide bottles,oil bottle,cosmotics bottle,wide-mouth bottles

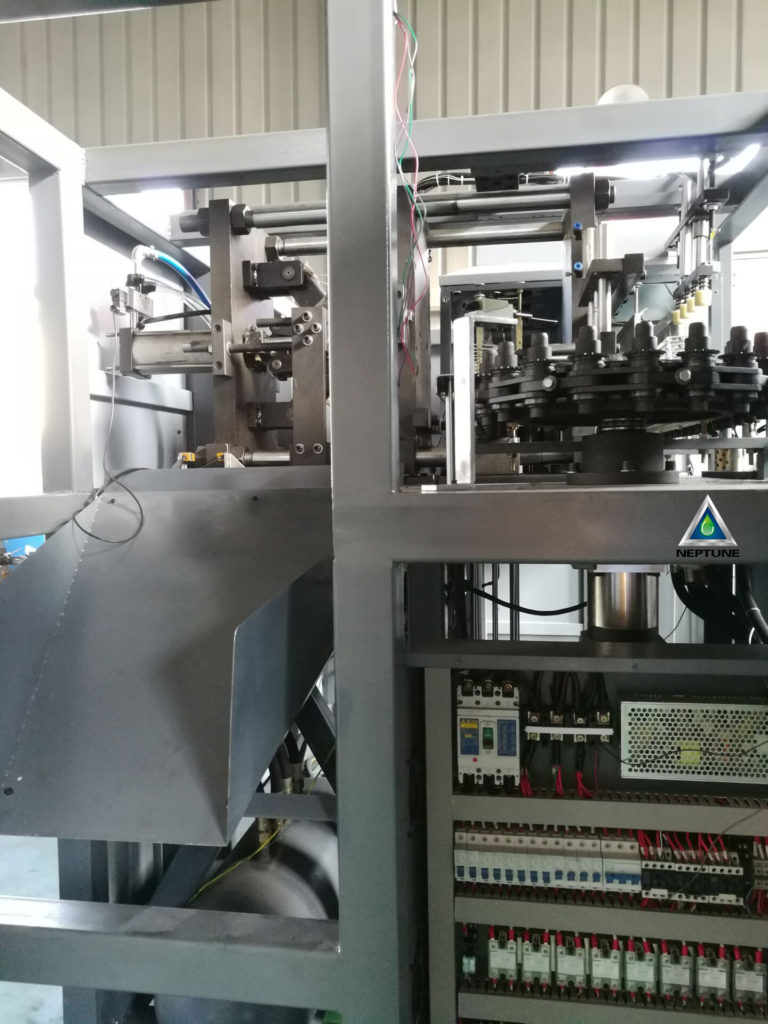

All-in-one system

- High Production Efficiency: Optimized design for rapid bottle production.

- Energy Savings: Advanced technology reduces energy consumption.

- Versatility: Suitable for various bottle sizes and shapes.

- Precision Control: PLC system ensures accurate molding parameters.

- User-Friendly Interface: Intuitive controls for easy operation.

- Low Maintenance: Durable components require minimal upkeep.

- Space-Saving Design: Compact footprint for efficient factory layout.

- Cost-Effective: Streamlined production process lowers manufacturing expenses.

BM-A1 Automatic Blow Molding Machine

Volume of product:0.1L-5L

Production capacity:500-1200BPH.

BM-A2 Two Cavity Automatic Blow Molding Machine

Volume of product:0.1L-2L

Production capacity:1800-2000BPH.

BM-A4 Four Cavity Automatic Blow Molding Machine

Volume of product:0.1L-2L

Production capacity:3200-4000BPH.

BM-A8 Eight Cavities Automatic Pet Blow Molding Machine

Volume of product:0.1L-2L

Production capacity:8000-9000BPH.

SETTING OF AUTOMATIC BLOW MOLDING MACHINE

1).PLC: Mitsubishi/SIEMENS.

2).Pneumatic parts: FESTO.

3). Operating system: LG.

4) Relay: OMRON.

5). Infrared thermometer: AMERICA RAYTEK.

6).Other electric parts are all world-famous brand.

7). Servo motor National (JAPAN).

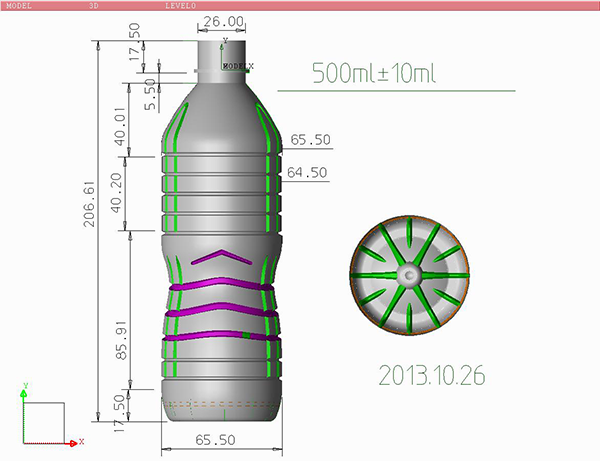

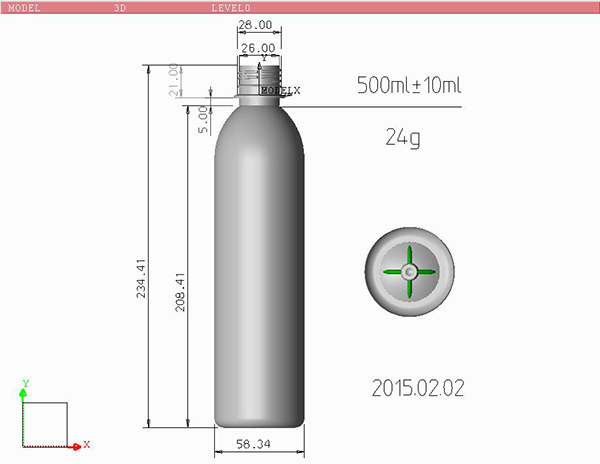

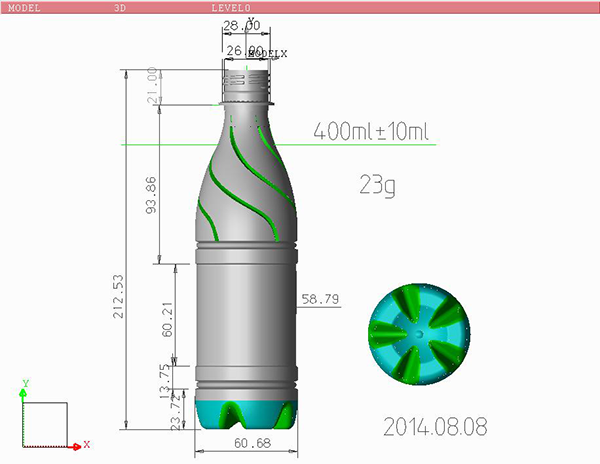

Free choice bottle drawing

CONFIGURATIONS OF THE BLOW MOLD MACHINE:

Air-break switch: Mitsubishi Japan

Air-break switch contactor: Zhengtai China

Minitype breaker: Zhengtai China

Relay: OMRON Germany

Thermal overload reply: Zhengtai China

Option switch Schneider: France

Green directive button: Schneider France

Emergency stop switch: Schneider France

Normally open contact: Schneider France

Normally closed contact: Schneider France

Photoelectric switch: OMRON Germany

Travel switch: OMRON Germany

Proximity switch: OMRON Germany

Photoelectric switch: OMRON Germany

Transducer: FULIN China

Touch screen: LG Korea

PLC: LG Korea