It collect rinser filler and capper in one machine. Make sure clean water filling environment. It is the best sell water bottling machine for small bottle like 500ml and 1.5liter bottle.

Water Bottling Machine

1) Rinsing system: Rinsing gripper dial, separating water dial, water trough

2) Filling system: Liquid tank, filling valves, controlling rings

3) Capping system: Screwing capper, cap sorter, falling cap guide

General description of the 3in1 water bottling machine

The XGF Washing-Filling-Capping (Three-in-One) Unit from our company is a state-of-the-art product developed by incorporating advanced technology from both domestic and international sources. This innovative unit, driven by a transmission motor, seamlessly integrates washing, filling, and capping processes. It boasts high automation, a compact and attractive design, user-friendly operation, and a safe and reliable performance. With an adjustable continuous production capacity, it’s an ideal liquid filling solution without gas. The unit is primarily designed for filling and capping polyester bottles, whether round or square. Its adaptable design allows for customization to meet the specific requirements of different users.

Main Technical Parameters of Water Bottling Equipment

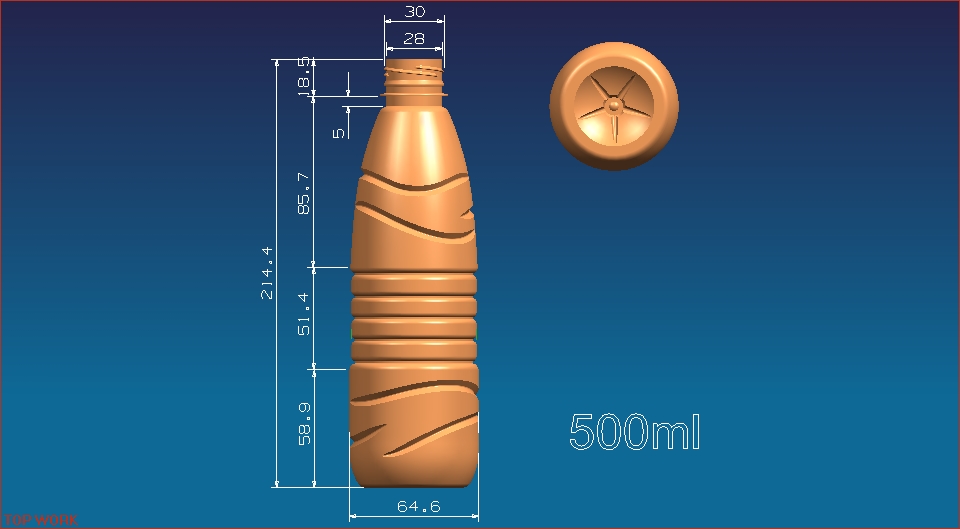

Capacity Scale of Bottle: 350—2000ml;

Diameter Scale of Bottle: ¢50mm–¢90mm;

Height Scale of Bottle:160mm-310mm;

Drink Kind: Mineral Water, Pure Water, Fruit Juice, Wine and other no-gas liquid

What is the production capacity of the 3-in-1 Water Bottling Machine for different bottle sizes?

The production capacity of a 3-in-1 Water Bottling Machine can vary based on factors such as the specific model, technology, and bottle sizes. Generally, these machines are designed to handle a range of bottle sizes from small to large. The production capacity is often measured in bottles per hour (BPH).

For accurate information on production capacity for different bottle sizes, it is recommended to check the specifications provided by the manufacturer of the specific machine model you are interested in. Manufacturers typically provide detailed documentation outlining the machine’s capabilities, including production rates for various bottle sizes.

Is the machine suitable for bottling water in various volumes?

Yes, the 3-in-1 Water Bottling Machine is designed to be versatile and adaptable for bottling water in various volumes. By changing the shape of the mold, the machine can accommodate different shapes and sizes of bottles, ranging from 200ml to 2000ml.

Additionally, it’s beneficial that all the necessary spare parts come with the machine, ensuring a seamless and efficient bottling process for different bottle sizes without the need for additional purchases.

Is the machine adaptable to different types of caps for various bottle sizes?

Yes, the machine can be adapted to different types of caps for various bottle sizes. However, it’s important to note that adapting the machine to different cap types may require additional spare parts, and there might be an extra cost associated with obtaining these parts. Additionally, changing caps can be a process that requires time and the expertise of professionals.

As a practical suggestion, many successful bottled water companies often choose to maintain consistency in cap types across different bottle sizes. This not only simplifies the production process but also streamlines inventory management and reduces complexity in the overall operation, similar to what many popular and large bottled water companies practice.

Does it have a user-friendly interface for easy operation and control?

Yes, the 3-in-1 Water Bottling Machine typically comes equipped with a user-friendly interface for easy operation and control. Modern machines are designed with intuitive control panels that allow operators to efficiently manage and monitor the bottling process. These interfaces often include touch screens or user-friendly buttons, making it straightforward for operators to set parameters, monitor production, and troubleshoot if needed.

To ensure that the machine meets specific user requirements and preferences, it’s recommended to review the documentation provided by the manufacturer, which usually includes details about the user interface and operational features. Manufacturers aim to make their machines accessible to operators with varying levels of experience, contributing to the overall efficiency of the bottling process.

(3-In-1)Water filling machine working process

The monoblock filling machine works as follows: Bottles are fed from conveyor chain into the filling machine monoblock via star wheel. Bottle clamp installed on the rotary wheel of the rinse will grip bottle mouth and make a 180° turn along a guide track to face the bottle mouth downward. In designated section of the rinse, rinsing water will jet out from special nozzles to flush bottle inside wall. After rinsing and dripping, bottles gripped by bottle clamp will make another 180° turn along a guide track to resume bottle mouth facing up position. Clean bottles are discharged out of the rinse by a star wheel to feed the filler. After entering the filler, bottles are retained by neck supporting carrier plates, which are actuated by bottle carrier mechanism to raise them to engage with filling valves. Filling valves are opened by bottle presence signals.

After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process. Bottle carrier mechanism is lowered by a cam to disengage filled bottles with filling valves. Then bottles are transferred into the capper by a neck handling star wheel. Anti-rotation blades on capping heads will seize the bottleneck to prevent it from rotation and hold it in a upright position. The twist-on capping head will make revolving and rotating movement along with the machine to finish the complete capping process of cap picking, placing, twisting, and disengaging under the control of a cam. A discharge star wheel discharges finished bottles onto discharge conveyor belt to be conveyed out of the filling monoblock.

Main features of the water bottling machine.

1.Bottle in feed

1) Bottle in feed by combination of in feed screw and in feed star wheel

2) Equipped with bottle jam protection device.

2.Rinser

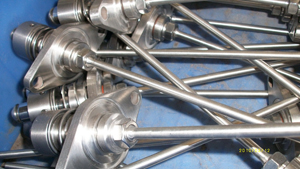

1) The rotary wheel is a fully AISI304 stainless steel welded structure.

2) The high efficiency atomizing spray nozzle installed on bottle clamp incorporating technology from Spaying Systems Co. Ltd., is capable of cleaning any part of bottle inner wall, and also saves rinsing water.

3) Covering of bottle clamps and elevator are product of IGUS

4) The rinse is driven by driving system positioned inside machine frame via gear transmission.

3.Filler

1) The filler is designed and manufactured with application of Italy technology, providing hardware guarantee for securing product quality and reducing loss.

2) Rotary wheel are fully made of stainless steel AISI304.

3) Filling valves are designed and manufactured with German technology, made of AISI316L, featuring high filling accuracy and high filling speed.

4) Bottles are raised and lowered by cam controlled lifting cylinder. Valve opening mechanism is actuated by air cylinder.

5) All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing.

4.Capper

1) The capper is most precise part in3 in1 filling machine, because the quality of machine is important to running credibility and product quality.

2) The cover track has the device to prevent the reversal cover from passing and pick out the reversal cover. Meanwhile the photoelectric switch can stop the machine automatically when there is no cover on the track, by which it can avoid bottle without cover effectively.

3) It also has the bottle check-up switch. Together with cylinder on the joint of the cover track and cover lift, they can control the cover flow and stop it in case no bottle to reduce the quantity of cover.

4) Highly effective acentric way for cap sorting to reduce the abrasion.

5) It has the check-up device to control the cover lift.

5.Main configuration of the three-in-one washing filling capping machine:

1)Material of filling valve and liquid tank is 304

2) Main motor:National brand

3) Sliding bearing:Taiwan

4) Frequency inverter: MITSUBISHI

5) Touch screen:Taiwan

6) PLC: MITSUBISHI

7) Pneumatic components: Airtac

8) Seals:National brand

9) Photocell switch and proximity switch:Taiwan

Cap automatic loading and feeding machine

Key Features:

🚀 Automated Cap Loading:

- Say goodbye to manual cap handling. Our equipment automates the cap-loading process, significantly reducing labor and increasing overall efficiency.

🔧 Seamless Conveyor Integration:

- Enjoy a seamless transition from cap loading to the filling machine. The equipment features an automatic conveyor system that ensures a continuous flow of caps to meet your production demands.

🌐 Screw Cap Types:

- Designed to accommodate various screw cap types, our equipment is versatile, allowing you to use it with different styles and sizes of water bottle screw caps.

How It Works:

- Cap Loading: The Automatic Cap Loading and Feeding Equipment efficiently loads caps from the storage area onto the conveyor system.

- Automatic Conveyance: Caps are automatically conveyed from the loading station to the filling machine, ensuring a smooth and uninterrupted process.

- Seamless Integration: The equipment seamlessly integrates with your existing production line, enhancing overall workflow and reducing bottlenecks.

Raleted Machine

883 Bottled Water Filling Machine

PRICE $11000

Newest design monoblock bottled water filling machine for 200ml to 2000ml bottle water. It collect collect rotary rinser, filler and capper in one machine.

16-12-6 4000BPH Water Bottling Machine 3in1

PRICE $16930

Factory directly selling 3in1 water bottling machine help you save over 10 thousand dollar. No need 26930 dollar, just 16930 dollar to got the full set 4000bph 3in1 water bottling machine.

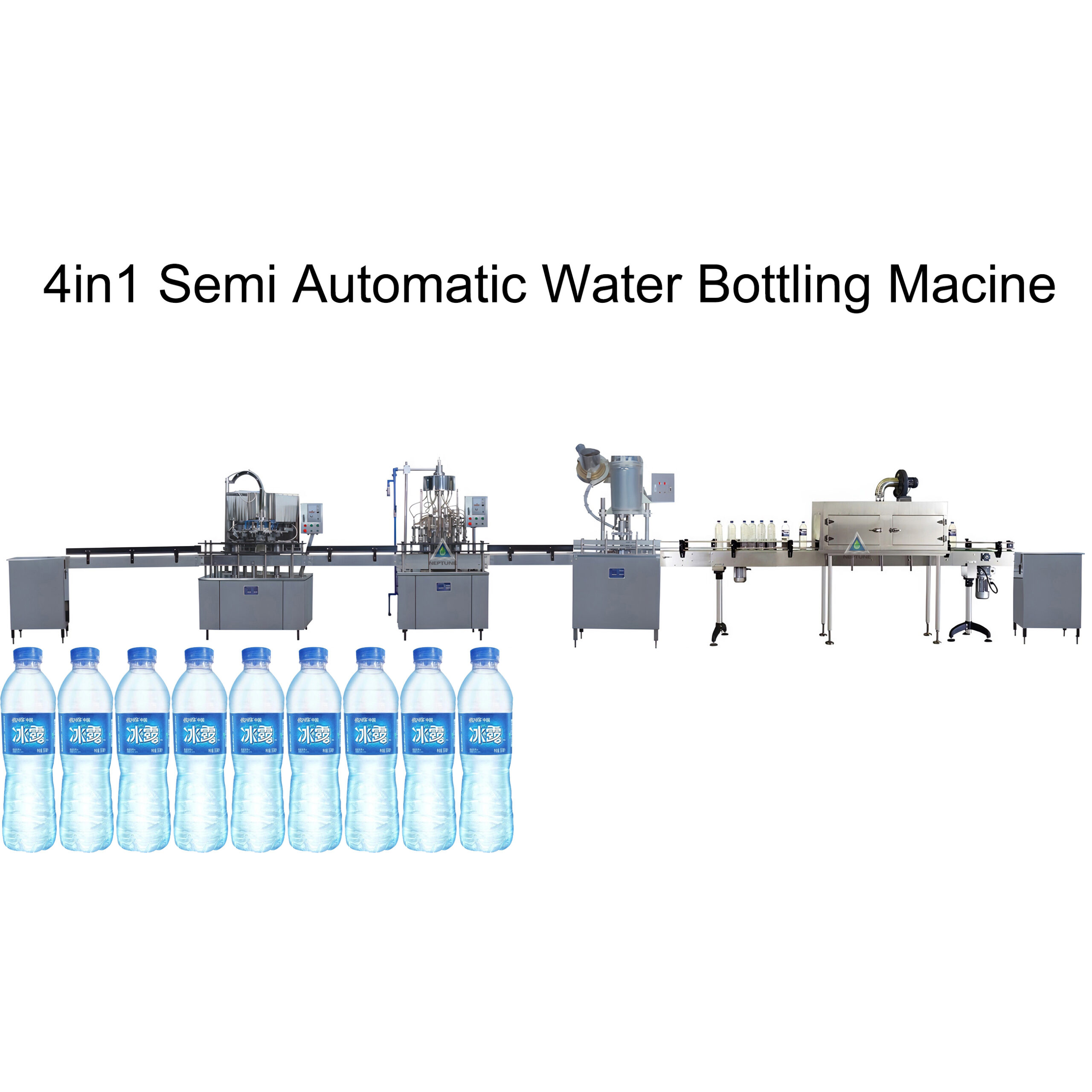

4in1 semi-Auto Bottle Rinser Filler Capper Labeler machine

PRICE $11000

4in1 Semi Bottling is a commercial semiaumatic water bottling machine used for washing, filling, capping and labeling any bottle range from 200ml to 2 liters.

Semiautomatic 2000BPH Water bottling machine

PRICE $9000

Water bottling machine linera type automatic accomplish whole process from washing, negative pressure, filling, settle cap, buckle cap till screw cap.