Plastic Bottle Automatic Sleeve Labeling Machine

Sleeve Labeling Machine (trapping label machine) is suitable for various kind of bottle types, for example round bottles, square bottles, flat bottles, curved bottles and cup-shaped bottles, etc.

Description of Sleeve Labeling Machine

New type bottle label steam shrinkage tunnel, label shrinkage steam machine, label steam thermo shrinkage tunnel, label steam tunnel, thermo shrinkage effciency greatly hence; regarding differ and abnormal round,square,flat bottle ect bottle type, adjustment and maintain is convenient, shrinkage is flat. New type bottle label steam shrinkage tunnel, label shrinkage steam machine, label steam thermo shrinkage tunnel, label steam tunnel, thermo shrinkage effciency greatly hence; regarding differ and abnormal round,square,flat bottle ect bottle type, adjustment and maintain is convenient, shrinkage is flat.

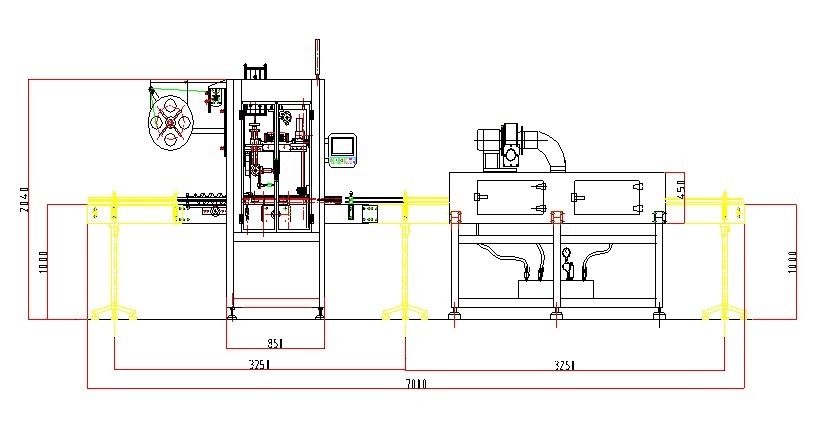

Sleeve Shrink Labeling System total 7meters

Features of Sleeve Labeling Machine,

1. The whole framework of the machine is made of stainless steel, and thus has a highly stable mechanical structure.

2. The labeling machine, is designed with a protective cover and man-machine interface operating system.

3. The machine can work with the whole production line and be fully coordinated with the whole line.

4. With unique knife plate design, the labeling machine saves the need of plate changing, within the scope of our specification.

5. With sleeve-label, the machine is very economical.

6. With an overall rotation system, the labeling machine is suitable for various labels with varied specifications.

7. Inner diameter of the label roll can be adjusted freely between 5″~10″.

Bottle types for Labeling Machine

The labeling machine is suitable for all kinds of bottle types, such as round bottles, square bottles, flat bottles, and more.

VIDEO of PVC Shrink Labeling Machine

Equipment brief introduction of the sleeve labeling machine

1.Synchronized transmission, any change of transmission belt will be finished quickly. Compared to the type of traditional multilayer whose change and maintain need more than six hours ,it’s maintenance is easy and maintain is simple ,so it doesn’t influence production.

2.Unit cutter head plane design inChinawhich apply to the container of ∮30mm—∮130mm.you never need to change or debug it. It also has unique light touch human-machine screen, that means, auto search original location as well as safety and convenience which is ahead of other congener products.

3.Single shrinking label feed plane ,rensonal height which is convenient to fix the label; micro-computer auto figure which avoid enactment and adjustment .you only need to press it lightly ,the label will detect and locate automatically. The change of label is quick and convenient, besides, the cutt place is absolutely exact .

4.Label feeding equipment: driving synchronized tensility control the supply of label ,the supply ability is 90meters per minute, volume label supply plane is ∮500mm,the internal diameter of paper tube will be4’,8’,10’.the configuration of label feeding is stable tensility which enable the exact length of label and the stable ,quick supply of label.

5.The center pillar apply step by step shoot label structure and the speed is 150B per minute. The newly designed cutter head use step by step motor driving which speed is high ,action is exact, the cut is in order and the shrinking is beautiful. This design coorperate with the label synchronized location structure enable the precision of cut location within1mm.

6.Many emergency stop buttons enable emergency stop at the proper position along the production which gurantee the safe production.

Special designed heat wind shrinking tunnel use high pressure wing machine which makes the shrink effect perfect. Compare with the traditional shrink tunnel which cannot shrink curved bottle, this head wind shrink tunnel can make the shrink effect satisfying.

7.The new style steam shrink tunnel improve the efficiency highly. It applies to different and unequal round bottle ,flat bottle ,square bottle etc. The adjustment and maintain is convenient ,the shrink is in order. The spout of steam use use the separation style which make the tunnel smooth. The spout mouth is divided into four parts and the height ,place and quantity of steam of every part can be adjusted in order to make the shrink effect perfect .the low pressure steam bag use the seamless steel tube design and every connect tube use stainless steel soft tube ,so the disassembly and fixing id very convenient. The whole machine is made of stainless steel ,so it is heat preservation and save energy sources, besides ,it accord with the international safety standard. The stainless steel plane at the bottom can condensate water and drainage them. The reductor and transportation machine is made by international famous brand—Spirax Sarco which working environment cannot be influenced. there are two eye window in front and at the back of the box body. the waterproof design of the whole machine is made of stainless steel which makes the operation and maintain convenient.

PVC Label Material

Example Use Shrink Labeling Bottle Water