AS1000 Sachet filling machine

Normal type

Fob price $ 1,350.00

AS2000 Pouch filling machine

With photocell monitoring type

Fob price $ 1,900.00

What’s the difference between photocell monitoring sachet packaging machine and none photocell monitoring one?

Photocell monitoring sensors are used to identify the marks on the sachet / pouch printing to make sure each product is in the same look, while the none photocell monitoring can only cut and seal in the preset length.

Where can I find the source of consumables, say PE film of the sachet filling machine?

To save shipping freight, we would recommend our customers to find the PE film locally, but we also offer PE film including printing at a competitive price, and if you are into the most popular sachet / pouch pure/mineral water business, we can also offer you a total solution including the water treatment, sachet / pouch filling machines, packaging plastic material and even factory design. Pls consult our sales engineer for more info.

Introduce of the Water Sachet Filling Machine

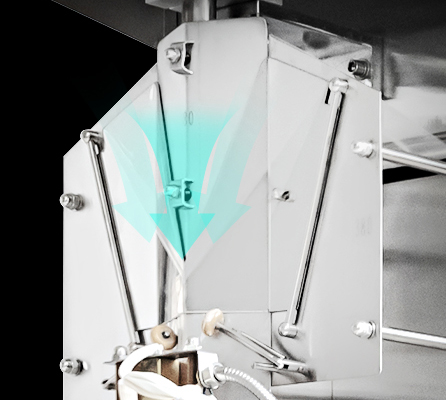

Water sachet filling machine is widely used for various kinds of liquid packaging, Such as, milk, soybean milk, fruit juice, beverage, ice drink, soy sauce, vinegar and wine. It uses single lay film PE as packaging materials. It can automatically sterilized by ultraviolet radiation,bag molding,print the code,precisely fill,seal and cut at one time .This series has been long-tested and its performance enjoys a very high reputation from our clients that this series is easy to operat and run smoothly with low failure rate.

Les parties de traitement de cette ensacheuse automatique sont toutes fabriquées en acier inox.

Le remplissage de pompe, la fermeture thermique, la fixation de la taille de sac, l’emballage,

la régulation de température, la fermeture et encore d’autres processus sont commodes et fiables.

Fermeture en dos, capable d’imprimer la date de production. Elle utilise le plastique polyéthylène.

Elle convient à emballer la sauce de soja, le vinaigre, vin de cuisine, vin, l’alcool désinfectant,

le jus de fruit, lait,yaourt, lait de soja et autres produits liquides.

Sachet Filling Machine Technical parameters

Yield capacity: 1500~2200B/H

Packing volumn: 100~500ml/B

Filling precision: ±1%

Film width: 240mm or 320mm(optional or choose others)

Power:

Moter: Singel phrase, Three phrases 1.1KW

Vertical hot seal: 0.3KW;

Horizonal hot seal: 0.5KW

UV sterilizer lamp: 1.5KW

Power supply: AC220V/Hz or AC380V(three phrases)

The weight of the machine: 360kg

Normal Type Dimension(L×W×H): 750*700*1700mm

With photocell monitoring type Dimension(L×W×H): 750*700*1700mm

Funcation

Bag (sachet )-forming

UV sterilization

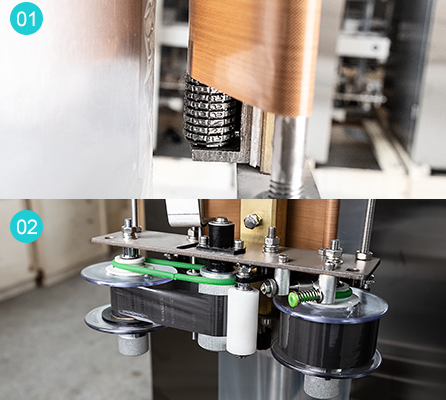

Thermal vertical sealing

Date lamination

Linear bag traction

quantitative filling

Thermal transverse sealing

Bag-cutting

Automatic counting

Sachet water packing machine and water pouch packing machine are generally used as filling machines for milk, juice, beverage, soybean milk and wine, etc. Operation Gist(In order to do seo.sorry about that we use different name of this machin to descripe)

1.The pouch filling and sealing machine installs at aeration and dry place, is full of sunshine, makes it stable. This automatic filling machine can fix four feet if neccessary

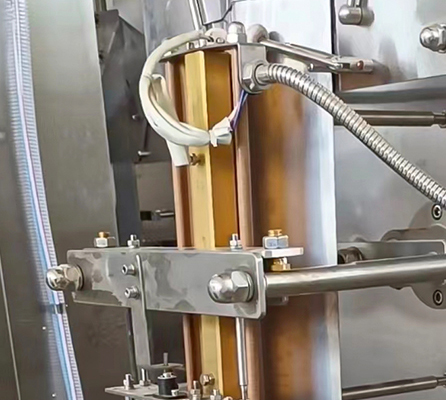

2.The tube which is going to fill material fills full of water(or75℃alcohol),the rubber tube cover the material out(avoid horinzon seal copper cake)and then lead to sewer(or recycle).The bagging equipment takes 5-10minites to wash pipe while starting the machine.It makes sure to reach the standard of food sanitation.

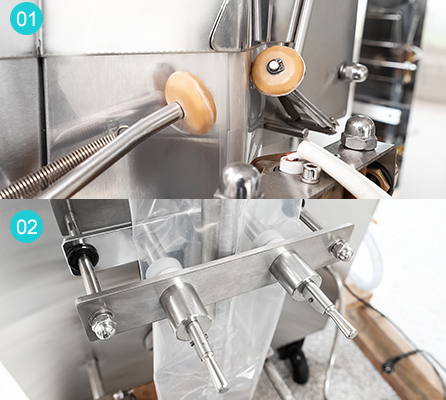

3.The plastic rool insert to the wheel, and adjust the central line, and make sure the same width when the roll is molding. Then screw the bolt separately. It is good through adjusting the pole of spring stress, ration automatically sway automatically. It is the best for braking well.

4.The sack pass through the tube, then buckle shaped utensil to make sure the strip symmetry. Date adjust to the daily date from up to down yearXX monthXX dayXX.

The vertical hot seal temperature adjusts to 120~150℃,the horizonal seal temperature adjusts to 180~240℃(No more than260℃, or the head of hot seal film is easy to damage),the exact temperature will be adjusted according to the film material and thickness.It can start to fill after pre-heat 20 minites, then it can produce continuously as long as the power is not off.

5.This liquid filling machinery can get the length of sack through adjusting the positon of pole on the winch.Adjusting-in is short, adjusting-out is long. First the power is off, then adjust. First loosen nut then adjust knob. Screw down the nut before starting the machine.

6.The sachet water filling machine can get the filling volumn throught adjusting ration pump on the winch. Adjusting-in is reduced, adjusting-out is enlarged. The same method with 5.5.

7.The piston is adjustable module. When it used for a peroid, if it is found the piston pole droped, you could loosen the screw on the end piston. Screw piston clockwise, it makes piston large and it will eliminate the phenomonon of drop. ( Note: the adjusting must be small, or the piston is easy to damage). Screw down the screw to prevent loosening after adjusting.

8.The liquid sachet filling machine is ok to press the button and no need workers when it works. The output will show automatically by the counter. The the film is used up, it need to stop at once, and change into another film, then provide liquid and the machine starts.

The sachet packing machine needs to pre-treat and filter when the solid substances is more in the tube which fill the liqui.When the vertical and horizonal seal no viscidity is worn after a peroid, it may loosen the tube to adjust. The bag filling machine can work after screwing down.( it is useless to adjust when it is worn completely). The liquid in the tube can not be more than 0.5meters to insure the precision. The bag filling machines can not be close when starts the machine, and when it has control valve in the liquid pipe.

9.Inspect the vertical and horizonal seal copper cake in a certain time, and clean up the sundries. Or the small bag filling machine will affect the hot sealing. The bag filling and sealing machine can not be cleaned with metal tool and sand paper, or it will damage the surface and can not work.

The bag filling machinery should be cleaned with cloth or wooden organic solvent after the temperature is down, and clean up the sundries.

10.The bag packing machine should rub methylsilicone oil on the vertical and horizonal seal cloth with a certain time, in order to prolong the life of no viscidity cloth and increase the hot sealing.(methylsilicone oil model:210~350CS)。

11.When it appears non-well seal, one sack connects another sack, leakage etc. it forbids pick it up with hands and kinds of tools. The liquid filling machinery should be stoped at once.

12.The automatic bag filling machines is the best condition of all the programme and dimension before delivery. If it needs experienced technician to maintenance, and write down the dimension, then it can take down.